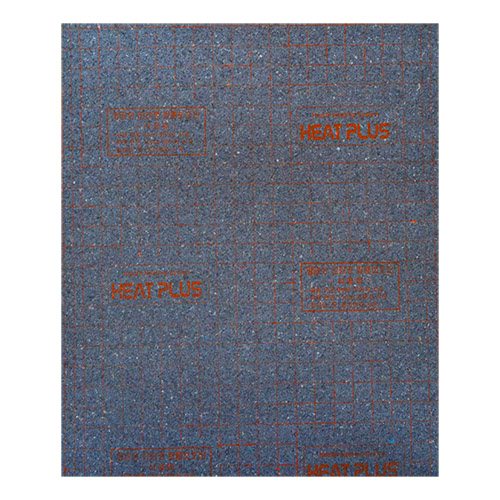

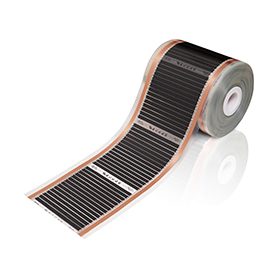

Heat Plus Premium Khaki is an infrared film of high power with a continuous carbon layer. It is used as a heating element in heating, heating and warm floors. In combination with other materials TM Heat Plus, it is ideal for laying as under light coatings (linoleum, laminate, carpet, parquet, etc.), and on the screed under heavy ceramic coatings.

- laminate

- linoleum

- parquet board

- carpet

- cement screed

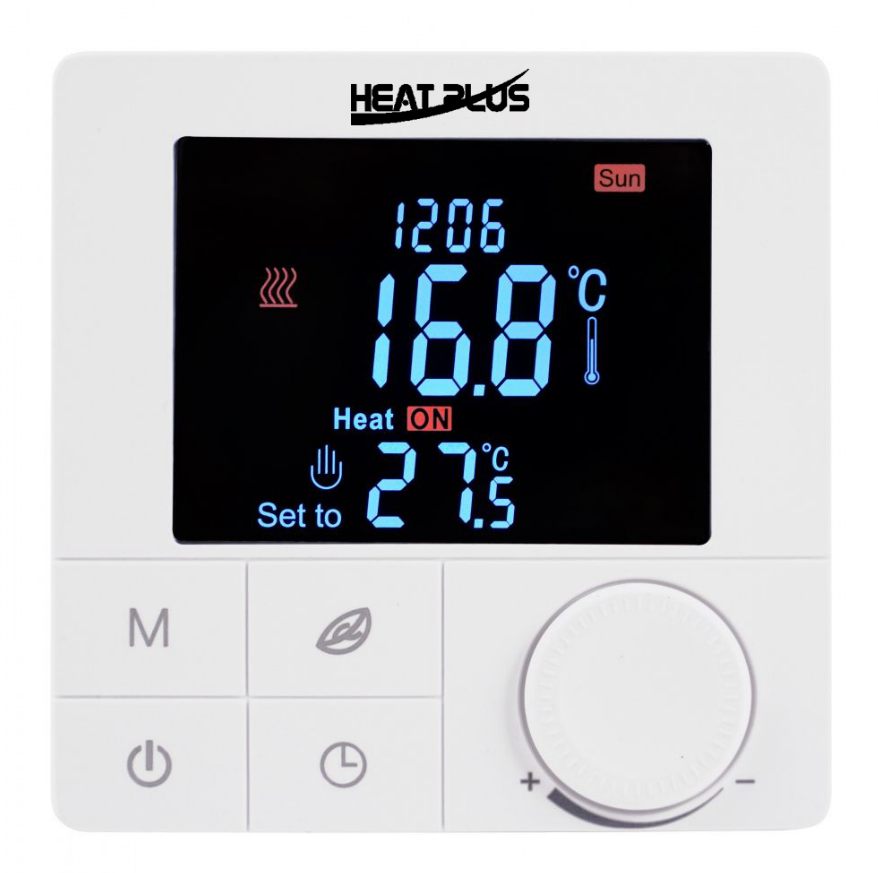

- +50°Сmax

- 220W/sq.m.

- 100 cmwidth

- 20 cmsection

- 220 V50 Hz

characteristics

| Power, W/m. | 220 |

| Max. heating temperature,°С | 60 |

| Collection | Infrared floor under the tile and screed |

| Type | Premium, covered, solid. |

| Application of the carbon layer | Solid |

| Operating voltage, V | 220 |

| Efficiency, % | 98 |

description

Hit Plus Khaki is a premium film with ionizing coating, created using the technology of solid carbon deposition. Due to the multilayer structure it has an increased resistance to high temperatures. This film is technologically designed for use under light coatings (laminate, linoleum, parquet, carpet, etc.) in places where heat is blocked. In other words, the Khaki film can be stacked even under stationary furniture, without the risk of damage to the film as a result of overheating. The principle of the Heat Plus Premium heating film is based on the conversion of electrical energy into thermal infrared radiation. The key role in this process is played by the carbon layer, which serves as a converter of electricity to heat. The efficiency of a film-based heating system is more than 90% - this means that with the same energy consumption you get more heat than from any other heating systems. This is achieved by eliminating losses during the transfer of energy from the source to the heat radiator. Direct heating of the floor covering and surrounding objects creates a comfortable temperature layer for human stay and reduces the need to heat the entire volume of air, in contrast to convection systems. The heating film does not heat the air, but the surrounding objects (floor, walls, furniture ...), which, subsequently, give their warmth to the air. During operation, the system does not burn oxygen, does not pollute the air and has a favorable effect on the microclimate in the room. People who are in the room where the Heat Plus heating system is installed, always feel warm and comfortable thanks to not only the heat, but also the process of ionizing the air with a film. The premium class of films from TM Heat Plus is especially strong and highly efficient infrared films of the third generation, which significantly exceed, in all respects, the Standard class (striped infrared films of the first generation). The heating carbon layer in Premium films is thicker and more ductile. And due to continuous application, the carbon layer is 2 times more efficient than that of the Standard film. The film in its structure has more layers and is technologically more durable and reliable. Due to the multilayeredness and new production technology, it was possible to significantly improve the safety parameters of use. So the melting temperature of the film increased by 100-120 degrees. If you compare the Heat Plus Standart film - this figure is 160 degrees, and for Premium film - 260-280 degrees. Heat Plus Premium infrared heating film consists of safe and environmentally friendly materials and is a film thickness of just 0.5 mm, consisting of 9 layers (unlike analogues, which consist of 2-3 layers). Due to a special structure, both superheating on films with a high specific power and the effect of local heat blocking on the film itself are minimized. In simple words, placing furniture or other objects on a film does not do any harm to it. The width of the Premium film is one meter. The design of the film allows you to divide it into two strips, each of 0.5 meters. Due to this, there is a flexible approach to the use of a half-meter film in narrow places or in heating appliances, or to fill the space with a meter film as much as possible. The cut lines of the film are widthwise every 20 cm, but technologically it is possible to cut them on any stripes and even obliquely. The most important part in the construction of the infrared film is the place of contact between the current carrying copper bus and the carbon heating layer. Reliable contact is provided by a silver tire, which completely covers the area of the copper conductor and ensures the absence of an air gap. Due to the high quality of the copper conductor, the lowest contact resistance (0.1 Ω) is reached, which minimizes the electrical losses at the contacts.

characteristics

main

| Max power | 220 W/m2 ± 10% |

| Working temperature | 50-60 t, °С |

| Efficiency, % | 98 |

| unit of measurement | linear meter |

| Cutting | is a multiple of 20 cm in length |

| Width | 1,0 m or 2 lanes of 0.5 m |

| Film thickness | 0,4 mm |

| In a roll | 75 m |

| Roll weight | 43 kg |

| Type of film | Premium, covered, solid. |

| Type of heating | Basic, additional |

| Guarantee | 15 years |

| Lifetime | 50 years |

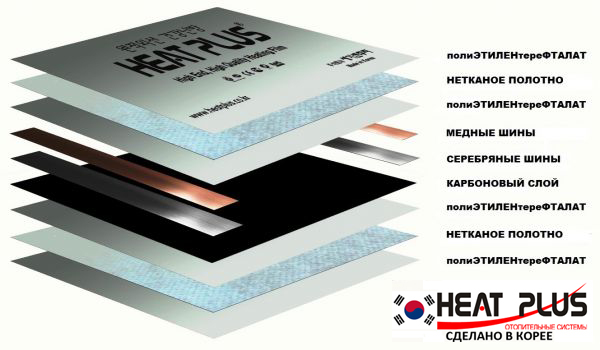

| Composition | Polyethylene terephthalate (PET), polyethylene (PE), copper conductor, carbon (carbon strips), polyethylene (PE), non-woven fabric, polyethylene (PE), polyethylene terephthalate (PET) |

others

| Collection | Infrared floor under the tile and screed |

| Product of | South Korea |

| Manufacturer | HEAT PLUS |

| Guarantee | 15 yeaes |

| Vendor code | 310000 |

film structure heat plus

- polyethylene terephthalate

- copper tires

- silver tires

- carbon bands

- polyethylene (PE)

- non-woven fabric

- polyethylene (PE)

- polyethylene terephthalate

features of the infrared film Heat Plus Premium

- The material consists of 8 layers;

- Melting occurs at 280 degrees;

- The sections, of which the film consists, have a width of 0.3 m.

- The material has a high level of reliability at average market value.

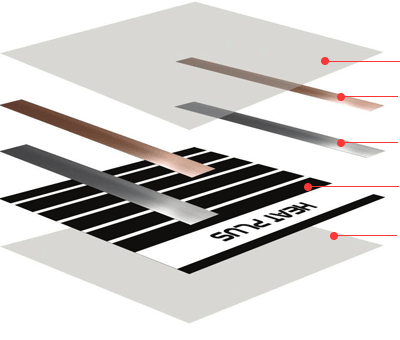

technology of using infrared film APN-410-220 Khaki

The heating material is arranged in such a way that heat can spread both upward and downward. In order to not waste energy in vain, a layer of thermal insulation (a substrate) is laid under the material. In our store you can buy branded thermal insulation materials, which you can see in the catalog of goods.

the heating film Heat Plus Premium APN-410-220 Khaki is used for the following purposes

- Arrangement of a warm floor;

- Equipment of additional heating systems in the premises;

- Heated walls, loggias, balconies;

- Systems of heating of agricultural buildings, devices for growing plants;

- Organization of heating in pavilions, shops, kiosks, garages, etc .;

- Ceiling heating device.;

installation of infrared film Heat Plus Premium APN-410-220 Khaki

It is carried out in accordance with the instructions in the instructions that are attached to the material. For installation, the accompanying materials are used - thermal insulation substrate, protective coating, etc.

The thickness of all layers is different. It depends on the features of the finish material:

- For parquet and laminate flooring - 0.45 cm.

- Under the linoleum, carpet - 0.65 cm

- Under the cement screed - 0,22 cm

materials required for installation of a floor heating system

for laminate, parquet board

when working with infrared film, safety measures should be followed

forbidden

- To install at an air humidity above 70%, and also on wet surfaces

- You can not use as a thermal insulation substrate, covered with foil of aluminum, metal

- It is forbidden to mount an infrared film on the surface of metal, polystyrene foam, polystyrene, mineral wool, textiles

- Make material kinks in the 0.5 m section by the value of the right angle or to the kink

- It is impossible to impose an infrared film in two layers, to cross the cloths

- Also, infrared film is prohibited from cutting in unauthorized places and placing heavy, sharp objects on it