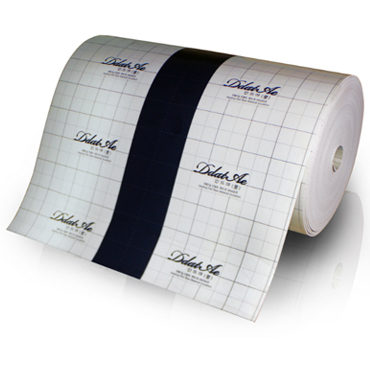

Polyethylene hose is used for additional protection of the infrared film from the aggressive influence of the external environment (screeds) when installing under heavy floor coverings.

The film is put on top with a 10-15 cm margin around the perimeter and is wrapped in an envelope. When the screed is dry, it protects the film from alkaline exposure and mechanical friction.

characteristics

| Thickness | 0,15 mm |

| Width | 1,5 m |

| Roll | 50 m |

characteristics

| Thickness | 0,15 mm |

| Width | 1,5 m |

| Roll | 50 m |

description

The polyethylene hose is used in the process of laying the Heat Plus infrared film under the screed for heavy floor coverings. The main task of polyethylene film is to protect the heating film from the aggressive impact of the screed.

Upon drying, the screed changes its geometric shapes, which can lead to mechanical damage to the infrared film. Using polyethylene as a layer - reduces the risk of damage. In addition, the concrete screed is an alkaline medium, which can also negatively affect the heating element in the system of warm floors.

When stacking the sleeve is cut to the canvas and mounted on top of the film strips, with a margin at the edges of 10-15 cm. Surplus of the film is turned inward, creating an envelope. In this configuration, the Heat Plus film is reliably protected from environmental influences.

Due to the minimum thickness (0.15 mm), polyethylene has virtually no effect on the passage of infrared radiation.

characteristics

| Width | 1,5 m |

| Length | 50 m |

| Thickness | 0,15 mm |

| Density | 150 g/m2 |

| Temperature mode | from - 40 to +70 ℃ |

| Thermal conductivity | 0,3 W/m•К |

composition

Polyethylene.

Stacking

Under the screed to protect from the effects of the external environment.

Fits stacked on top of the infrared film and wrapped in an envelope.