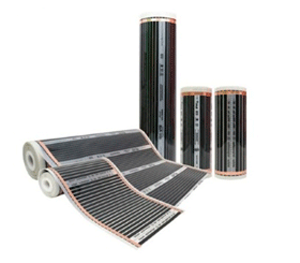

Heat Plus ECO film is used as a heating element in heating, heating and warm floors.

In combination with other materials TM Heat Plus, it is ideal for laying under light coatings (linoleum, laminate, carpet, parquet, etc.).

Also, it is possible to use a film under the screed, for laying heavy coatings (tiles, marble, etc.).

The width in the standard film class ranges from 40 to 100 cm, which makes it possible to lay in any places, including narrow passages, and to apply film in heating devices.

The maximum power from 30 to 300 W / m., Which allows you to flexibly approach the use of the film, applying it both to objects with low permissible power, and in rooms with a sufficiently high heat loss. The principle of the action of heating film Heat Plus Standart is based on transformation of electrical energy into thermal infrared radiation. The key role in this process is played by the carbon layer, which serves as a converter of electricity to heat.

The heating film does not heat the air, but the surrounding objects (floor, walls, furniture ...), which, subsequently, give their warmth to the air. During operation, the system does not burn oxygen, does not pollute the air and has a favorable effect on the microclimate in the room.

People who are in the room where the Heat Plus Standart heating system is installed, always feel warm and comfortable thanks to not only the heat, but also the process of ionizing the air with film, due to the silver layer.

The efficiency of a film-based heating system is more than 90% - this means that with the same energy consumption you get more heat than from any other heating systems. This is achieved by eliminating losses during the transfer of energy from the source to the heat radiator.

Direct heating of the floor covering and surrounding objects, creates a comfortable temperature layer for human stay and reduces the need to heat the entire volume of air, in contrast to convection systems.

Heat Plus infrared heating film consists of safe and environmentally friendly materials and is a film with a thickness of only 0.338 mm, consisting of 5 technological layers (unlike analogues, which consist of 2-3 layers).

Carbon strips are united in sections of 20 cm in length. Carbon layer with a plasticizer is homogeneous, with great accuracy, applied to a PE (polyester) substrate. Overheating on films with a high specific power is eliminated.

The most important part in the construction of the infrared film is the place of contact between the current carrying copper bus and the carbon heating layer. Reliable contact is provided by a silver tire, which completely covers the area of the copper conductor and ensures the absence of an air gap. Due to the high quality of the copper conductor, the lowest contact resistance (0.1 Ом)